What Is An Earthing System?

Earthing and bonding are essential parts of a safe electrical system and they refer to the connection of the electrical conductors (wires) to the earth. This is done for the purpose of safety, as it prevents electric shocks and fire hazards from occurring. It’s important to note that earthing and bonding need to be maintained and checked regularly, as part of an Electrical Installation Condition Report (EICR).

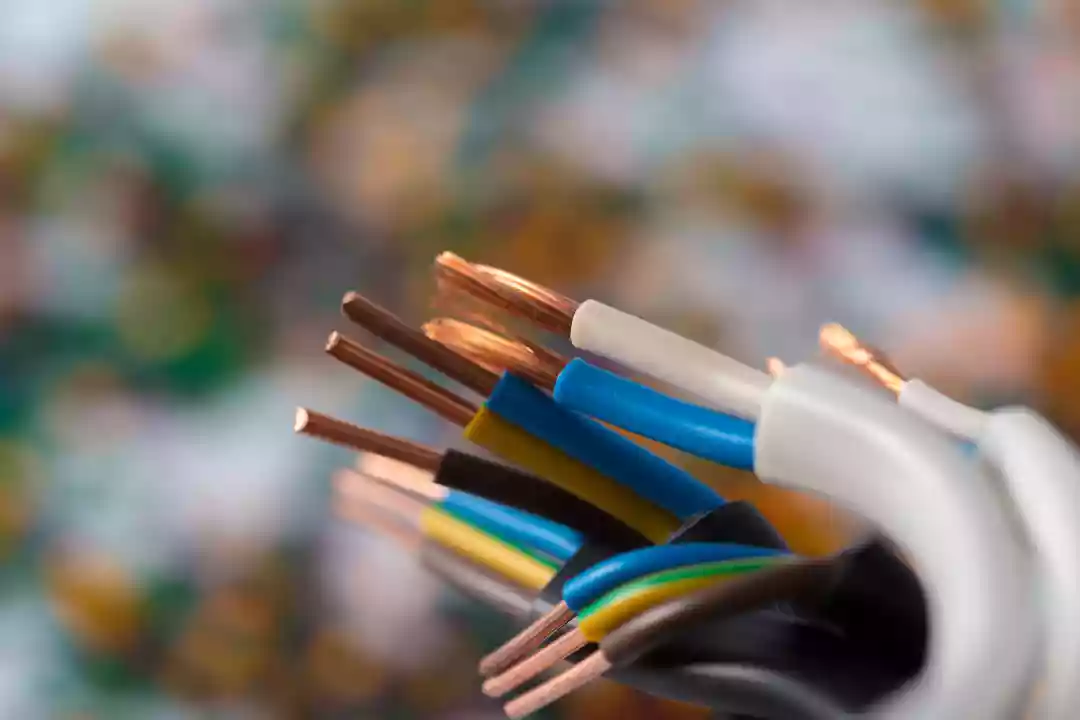

An earthing system begins by connecting metal parts of the electrical installation to a main earth terminal. This terminal leads to a rod which is driven into the ground to create a physical connection between the installation and the earth. The earth creates a safe path for any excess current caused by a fault in the wiring. Without this, it would have no place to go and could cause a hazard. Over the years, three main types of earthing systems have been developed - TN-C-S, TN-S and TT.

TN-C-S

In the UK, this arrangement is most frequently employed. It offers dependable and secure earthing for low voltage supply and goes by the name of protected multiple earthing (PME). With this arrangement, numerous users can share a single power cord. The protecting earthed neutral (PEN), which requires several connections to the earth throughout the supply path, has a voltage increase as a result of the increased current flow. Near the supply source, at the installation's intake, and at other critical locations throughout the distribution system, the neutral is earthed. The maximum external earth fault loop impedance is 0.35 since the DNO employs a mixed neutral and PEN return route.

Despite being widely used, the TN-C-S configuration might be dangerous if the PEN conductor develops an open circuit in the supply since there would be no direct route for the current to return to the substation level. As a result, there are several locations where its usage is prohibited, such as petrol stations, construction sites, RV parks, and some structures.

Need assistance finding electrical inspections near you?

Get a QuoteTN-S

The supply transformer is the closest neutral-to-earth connection in TN-S systems, and separate supply cables are used throughout. With low-voltage supplies, it is also possible to link the transformer to the supply cable's sheath, creating a unique path back to the substation transformer. In these setups, the maximum external earth fault loop impedance of the DNO is typically 0.8.

The "neutral" conductor (N) of a TNS earthing system is linked to the electrical supply, while the earth conductor (S) is connected to a metallic structure that is buried in the ground, such as a metal water pipe or metal rod. The "live" conductor (T) is linked to the electrical installation. The fault current will travel through the earth conductor to the ground rather than through the electrical installation or the people using it if there is an electrical installation failure (such as a short circuit). This lessens the chance of electrical shocks and electrical installation damage.

Any electrical project must include TNS (TN-S) earthing systems because they offer a secure and dependable connection to the ground that safeguards persons and property from electrical risks.

TT

Although it is set up similarly to the TN-S system, users do not receive their own unique earth connection. Customers must instead provide their own soil, for instance by burying rods or plates underground to provide a low-impedance route. When TN-C-S setups cannot be employed, as in the case of the gas station example above, or in rural locations where supply is given via overhead poles, TT systems are frequently used. When diverse soil types exist that may result in external earth fault loop impedance values, shock protection mechanisms like RCDs are frequently utilised to enable immediate cut-off of power.

The connection to the supply source and the load end or installation metalwork are both directly linked within this kind of earthing system. As a consequence, in the event of an overhead line, the earth's mass will act as the line's return channel. The neutral and earthing wires must be separated during installation since the power distributor only provides the supply neutral or protective conductor for the connection to the consumer.

What Is Bonding?

Electrical bonding is the process of purposefully electrically connecting all exposed metal objects in a space or structure that are not intended to transmit electricity in order to prevent electric shock. Bonding is further employed to reduce electrical arcing between metal surfaces with different electrical potentials. All joined metal items in the room will have almost the same electrical potential if electrical insulation fails, preventing a person from touching two things with noticeably differing electrical potentials. The passenger will be safe from potentially hazardous differences even if communication with far-off earth is lost.

All non-current-carrying metal equipment components should be connected to the earth ground at the main service panel to guarantee that current is redirected to the earth wire in a system with a grounded (earthed) neutral. When a direct connection exists between the installation earth and the transformer neutral in a TN system, earthing allows the branch circuit over-current protection (a fuse or circuit breaker) to quickly identify the problem and shut down the circuit.

An RCD must be utilised to provide disconnection in TT systems when the impedance is high since there isn't a direct connection to the transformer neutral. RCDs are also employed in other circumstances where a quick disconnect of a tiny earth fault is required, such as when a person accidentally touches a live wire or when there is damage.

In conclusion, it is essential to understand both earthing and bonding and their importance in maintaining a safe electrical system. Regular checks should be made during an EICR to ensure that the earthing and bonding system is functioning correctly. This will help to reduce the risk of electric shock and minimise the chances of a fire occurring.

In this article: