Importance Of Respirators

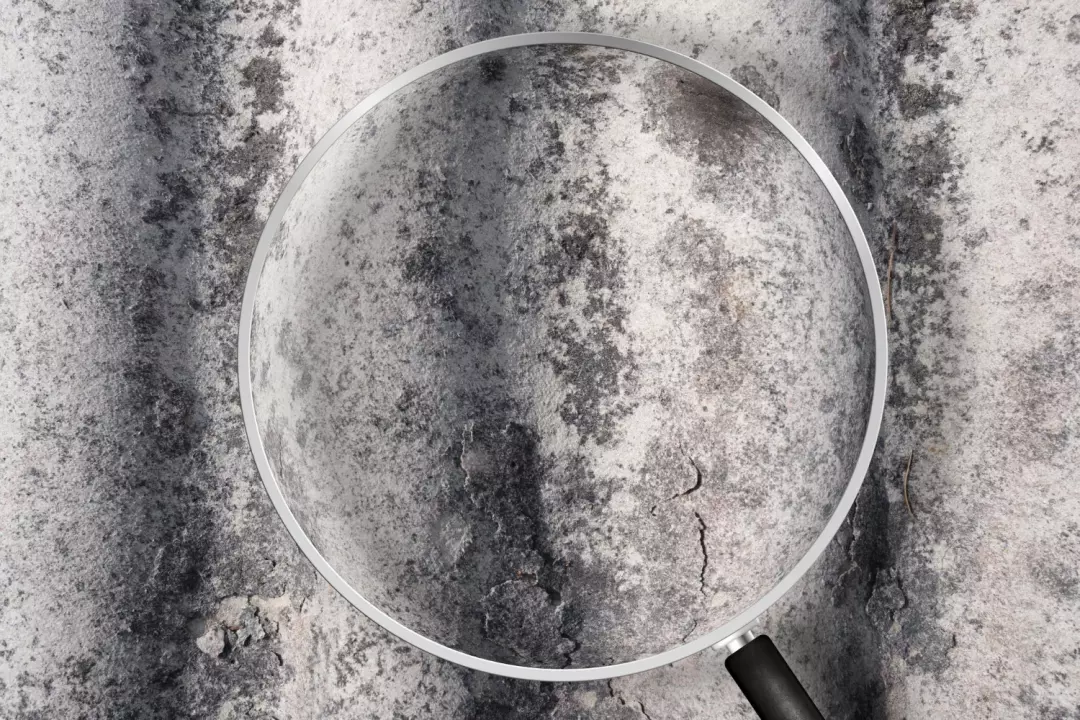

A material known as asbestos is composed of very minute threads that can be breathed into the lungs. Inhaling asbestos fibres can seriously harm your health and increase your risk of developing lung and mesothelioma cancer. This makes having the proper respirator when handling asbestos absolutely necessary. Workers need to wear respirators to protect them from dangerous substances. They shield employees from potentially inhalable pollutants including asbestos, mould, and other particles.

Even though the danger is small, this protection should always be utilised in locations where there is a chance of contamination. For instance, asbestos dust may be found on building sites as a result of the items being disassembled or relocated. Workers are more protected from inhaling any harmful chemicals when using a respirator. Additionally, respirators increase employee productivity. Employee productivity may suffer if they are using the incorrect sort of respirator. Workers can obtain the protection they require without sacrificing productivity if they use the proper respirator for the task.

What Is Respiratory Protection?

The precautions made to prevent employees from breathing in potentially harmful chemicals are referred to as respiratory protection. Dangerous dust, fumes, gases, mists, vapours, and low oxygen levels are only a few examples of these chemicals. Respiratory protection essentially entails employing equipment and procedures to make sure that employees are inhaling air that is secure and does not provide a health risk. Effective ventilation, the use of respiratory protection equipment (RPE) such as masks and respirators, and the enforcement of procedures and protocols for safe work in settings where respiratory dangers exist are just a few examples of precautions that may be done to safeguard the respiratory system.

The usage of respirators is one of the most critical parts of respiratory protection. Respirators are intended to keep the wearer safe from breathing dangerous pollutants. Because there are many types of respirators for different sorts of hazards, it is critical to select the proper one for the job. All respiratory protection components should adhere to the guidelines and norms set out by organisations that promote workplace health and safety, such as the Occupational Safety and Health Administration (OSHA). To promote worker safety, these organisations create thorough standards and guidelines for respiratory protection.

Need assistance finding asbestos removal near you?

Get a QuoteTypes Of Respirators

The most popular form of respirator is a disposable mask, which is normally constructed of multi-layered fibres coated with an oil-resistant adhesive. These masks should only be used once and are normally used for low to moderate exposure levels. Half-face respirators are intended to filter out particles from the environment and cover the lower portion of the face. Typically, workers who will be exposed to significant amounts of pollutants will utilise these respirators. Full-face respirators shield the user's full face from inhalation and exhalation risks. These respirators offer the best defence against airborne pollutants and are ideal for more dangerous conditions. Powerful air-purifying respirators (PAPRs) include an electric blower that draws air into the facepiece and through the filters. PAPRs are created to offer protection from a range of airborne contaminants and are available in a number of sizes and forms.

Air-Purifying Respirators (APRs)

In order to remove particulate matter and particular substances that the filter is intended to collect, air-purifying respirators (APRs) employ cartridges to filter the air in the user's surroundings. These filters cannot be utilised in places where there may be an oxygen shortage since they have no effect on how much oxygen is present in the surrounding air. Only the substances that the filter is intended to catch are eliminated. These respirators are made for circumstances where the concentration of the agent is either established to be or expected to be below the threshold for the canister since high concentrations of contaminants can overwhelm the filter's capacity.

A PAPR reduces the effort required to breathe and the danger of air entrainment near the respirator face piece by using a motor to draw air through the filter canisters. The loose-fitting disposable or reusable hood that is frequently included with PAPRs avoids the requirement for fit testing and enables usage by a variety of people. Because of their low cost, lightweight, and enhanced versatility of usage, hooded PAPRs with "stacked" canisters, which provide protection against typical hazardous chemical and biological agents encountered by first responders and hospital staff, are in popular use.

Elastomeric Full Facepiece Respirators

Elastomeric respirators are snug-fitting respirators that offer protection above N95 standards and are designed to be reused safely for many years. Online and in the media, elastomeric masks could be something you've been hearing about more and more lately. These reusable rubber half masks have been a standard component of personal protective equipment (PPE) for many employees across several sectors for decades. These reusable respirators outperform any disposable mask on the market in terms of dependability, comfort, affordability, and safety.

Numerous companies provide elastomeric respirators, which commonly employ N95, N99, N100, or P100 level filters. Due to the additional protection, they provide and the fact that they are more affordable than disposable N95s, these reusable respirators are the most popular ones to be found in homes and workplaces. They can frequently be found working in the mining, automotive, building, agricultural, pharmaceutical, and home improvement industries. Such rubber half masks are available online and at your neighbourhood hardware store.

While some elastomeric respirators are designed for industrial usage, others are built specifically for healthcare professionals, educators, and others who require the finest protection against dangerous infections, wildfire smoke, environmental allergies, and other hazards. It's critical to utilise the proper respirator when working with asbestos. Respirators come in a variety of styles, including disposable masks, full-face, half-face, and powered air-purifying respirators. Elastomeric full-facepiece respirators should be utilised for the best level of safety. In order to prevent contamination and maintain the respirator's functionality, it's also crucial to follow the right cleaning methods.

In this article: