What Is the Difference Between MIG and TIG Welding?

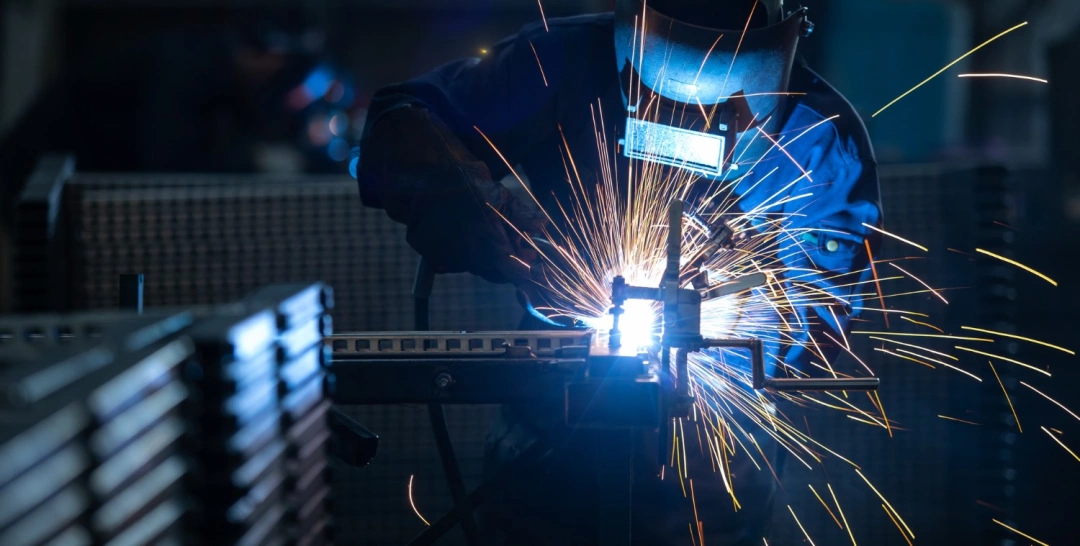

Welding is a process that joins two or more pieces of metal or thermoplastics by using high heat. It plays a key role in a wide range of industries, including construction, manufacturing, automotive repair, and even art and sculpture. There are many types of welding techniques, but the two most common are MIG welding and TIG welding.

Although both aim to create strong joints between metal parts, they use different tools and methods. These differences affect not only the appearance of the weld but also how easy each process is to learn and use. The type of shielding gas, electrodes, and how the filler metal is applied all vary between these two techniques.

Knowing the difference between MIG and TIG welding can help you make better choices when planning your projects. Whether you are a hobbyist or a tradesperson, understanding how these methods work and when to use them is important. By comparing their strengths, applications, and equipment, you can choose the method that best suits your goals and level of experience.

How Each Welding Process Works in Practice

MIG and TIG welding may appear similar, but the way they operate and what they require are quite different. Each method uses specific tools and follows a unique approach that affects the outcome and efficiency of the job.

MIG Welding: Metal Inert Gas

MIG welding, also called Gas Metal Arc Welding (GMAW), uses a wire electrode that is fed through a welding gun. This wire acts as both the electrode and filler metal, melting to fill the joint as the weld is created. The process is semi-automatic, with the machine feeding the wire while the user controls the torch.

A shielding gas, often a mix of argon and carbon dioxide, flows through the gun to protect the weld from air. MIG welding is quick, efficient, and ideal for thicker metals. It is common in automotive work, factories, and construction. Many technicians favour MIG for repetitive tasks where speed is essential.

TIG Welding: Tungsten Inert Gas

TIG welding, or Gas Tungsten Arc Welding (GTAW), uses a tungsten electrode that does not melt. Instead of using a continuous wire, the welder adds a filler rod by hand. This gives more control over the weld, especially on thin or complex materials.

Shielding gas, usually argon, protects the weld from contamination. TIG welding is used for detailed work, such as on bikes, furniture, or metal artwork, where appearance matters. The slower pace and need for both hands make TIG harder to learn but more flexible once mastered.

Main Equipment Used

MIG welding uses a machine with a wire feed, a spool gun, and shielding gas. It is easier to set up and more beginner-friendly. Many home kits are available for small-scale jobs. The learning curve is gentle, which makes MIG a good entry point for many welders.

TIG welding needs a torch with a tungsten electrode, a separate filler rod, shielding gas, and a foot pedal for heat control. This setup gives more accuracy but is more complex. It often requires more training and hands-on practice to become confident using the equipment correctly.

Type of Materials Welded

MIG welding works well with thick materials like mild steel, stainless steel, and aluminium. It is used in larger jobs that need to be completed quickly and solidly. It can even be used outdoors if conditions are calm and clean surfaces can be maintained.

TIG welding is better for thin metals and non-ferrous metals such as copper and magnesium. It produces clean, polished welds with little to no spatter. It is especially useful when welding pipes, kitchen fittings, or tanks where a clean joint is critical.

Need assistance finding welding near you?

Get a QuoteWhich Welding Method Offers Greater Precision and Control?

For projects that demand fine detail, TIG welding is often the best choice. The separate filler rod and foot pedal give the welder more control over the weld size and depth. This is useful for thin or delicate materials and tasks that must look neat.

TIG welding is widely used in industries where appearance and precision are important, such as medical tools or aerospace parts. It produces smooth welds with less clean-up needed. Even under close inspection, TIG welds often show no obvious flaws or rough edges.

MIG welding still offers good results, but is easier to learn and faster to use. It is better suited to jobs where the finish is not the main concern, but strength and speed are. For general work, MIG provides a good balance between control and ease.

In skilled hands, both methods can produce excellent results. However, the real advantage of TIG comes into play when the highest level of finish is needed. Its ability to create narrow, clean welds makes it a top choice in precision settings like instrument panels or food-grade containers.

Strength and Durability: Which Welds Are Tougher?

Both MIG and TIG welding can create tough and lasting joints, depending on how they are done. MIG welding usually creates thicker welds that penetrate deep, making it ideal for heavy-duty work such as vehicles or machinery. These welds are less likely to fail under weight or pressure.

Because MIG welding is fast and provides strong joints, it is often chosen for outdoor work or repairs. It is also more forgiving when materials are not perfectly clean. Welds created through MIG tend to be broader and filled with more metal, giving extra support in structural applications.

TIG welding can also produce strong welds, especially on thin or non-standard metals. It is less likely to introduce weak spots, cracks, or contamination, but this depends heavily on the skill of the welder. TIG welds usually require more precision to maintain their strength, but when done well, they are incredibly resilient.

In general, MIG is stronger for large, thick parts, while TIG gives strong, clean welds on light or delicate materials. Both are reliable when used properly. For best results, correct preparation and the right technique are essential, no matter which welding process is chosen.

How to Choose the Right Welding Method for Your Project

Choosing between MIG and TIG welding depends on your needs, skill level, and materials. Each method has benefits depending on the job. By understanding the strengths and limitations of both, you can avoid mistakes and make sure your project is successful from start to finish.

Project Size and Speed

MIG welding is better for large projects or jobs with a deadline. The automatic wire feed and fast process help cover more area in less time. It’s also easier for beginners to use effectively and allows for longer, continuous welds with fewer stops and starts.

TIG welding takes longer but offers greater control. It is perfect for small parts, detailed joins, and work that must look tidy without needing much clean-up later. If time is not an issue and quality is a priority, TIG is the preferred choice for many professionals.

Material Type and Finish

MIG welding is suitable for thick or rough metals. It works well even when surfaces are not fully clean. This makes it ideal for repair work and outdoor projects where prep work is limited and conditions can be unpredictable.

TIG welding gives a cleaner finish and works well on shiny or thin metals. If the weld will be visible or the project must look professional, TIG is the better choice. It also helps when the metal is sensitive to distortion, as TIG allows lower heat settings.

Skill Level and Cost

MIG welding kits are usually more affordable and simpler to use. Many beginners start with MIG because it is easier to learn and still offers strong results. Maintenance and setup are straightforward, and many machines are portable and reliable.

TIG welding equipment is more costly and may need more training to use correctly. However, for experienced users, TIG offers the best results for jobs that need care and accuracy. It is the go-to option for industries that require expert-level welds and where small errors could affect safety or performance.

In this article: